Rotax 159cc project

- 25 gen 2024

- Tempo di lettura: 4 min

Aggiornamento: 21 feb 2024

2022

Aim of the project: Having broken my original engine, I wanted to rebuild a definitive engine capable of delivering maximum power without compromises.

Description: The first step was therefore to take a big bore cylinder (154cc), criticized a lot, but after some targeted work it allowed the engine to deliver a power higher than the original ones.

The first step was to analyze the components of this kit, the piston one of the weak points as it was much heavier than the original and was a cast piston, it was replaced with a forged piston from a Quattrini ϕ60 made even lighter internally to bring its weight identical to the original Asso piston.

The piston already had a slot on the skirt which has been ported to the intake port in the cylinder.

The piston pin is another critical point as it was much thicker and heavier than the original ones, even taking the one supplied with the Quattrini piston it was too heavier.

I replaced it with one machined from 16CrNi4 considering the new weight of the piston with appropriate calculations was made conical inside to reduce even more so is the weight of the piston ring and pin assembly.

As for the connecting rod, the original was replaced with one more long 117mm, thanks to a company that allowed me to use an existing model with a 115mm wheelbase and lengthen it by another 2mm, the connecting rod was made in 40NiCrMo7.

Its particular shape has allowed the weight to be less than the original cast ones.

To reach a displacement of 159cc, not being able to act on the piston bore it was therefore necessary to increase the stroke, not wanting to change the crank, my idea was to create a pin with an offset for the connecting rod(2mm offset) bringing the effective stroke to 56.5 mm, working also on the crank to make conecting rod washers not colliding in it.

The crankshaft connecting pin was made in C25 and was studied as a weakened beam, then I used solidworks to check the results obtained on paper and to find the best radious to match the crankshaft.

The entire connecting rod, crank, piston, ring and pin assembly was rebalanced both dynamically and statically, also taking into account the flywheel and the countershaft which I wanted to leave with the original weight.

A laser-cut base was used to raise the cylinder from the crankcase by 5mm.

First prototype of the plate:

Having taken the original measurements I recreated a model of the sleeve to measure the timing expected later.

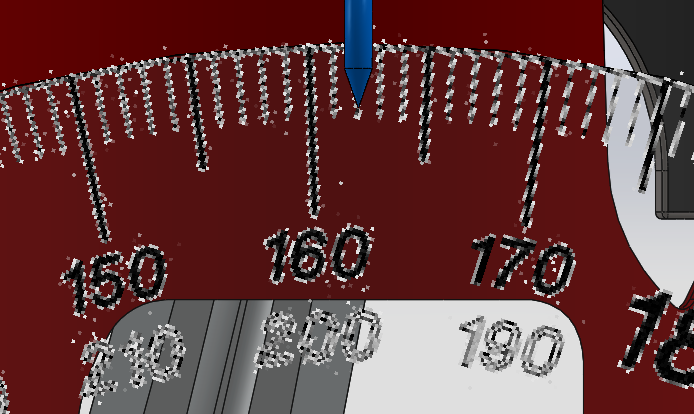

After these interventions, the model showed an expeted values of 198° for the exhaust and 135° for the transfer ports.

After mounting all the components the exhaust was 197° and transfers 136° not so different from the expeted ones.

0.3+0.15 gasket with 0.85mm squish

For the gearbox, reading the engine manual of an Aprilia RX 125 I noticed that 5th and 6th gears of the secondary shaft was both 1 tooth and 2 teeth less than the one on my engine, if coupled with gears of the primary shaft from my gearbox, were able to provide a transmission ratio that would have allowed me to reach a better top speed.

As regards the reed valve pack, I proceeded to replace the original one with a 4-petal KTM ones and to create a special flow guide here too after carrying out several simulations, the reeds were replaced with reeds from a 2002 KTM EXC 250 and top reeds were obtained from a Parma Kit W-Force reed valve, to have a larger opening and prevent breakage due to contact with the cylinder walls they have a different radius in the corners.

First prototype of the reed valve flow guide:

For the clutch, it has been lightened by approximately 200gr through appropriate ϕ24mm holes on its basket switching to titanium screws and a pressure plate machined from alluminium 6000 series, after having also carried out various simulations based on the expected loads of it, the weight has been reduced from the original 103gr to 58gr.

The bearing is a radial bearing, unfortunatelly there wasn't any angular bearing matching my requirements, it can look as a bad choise but the central point is used only as pivoting point, there is an actuator that push directly on the pressure plate so the bearing is used mainly for maintain the basket in position.

Then I found online a 3D scan in .STL format (Thanks to Ferenc Borsi) of the original cylinder, using Solidworks ScanTo3D extension, I was able to use this graphic file to convert the meshes (just over 83'000) and half them by approximately 65% 50'000 and extract features that would allow me to adapt my sleeve in this 3D scan, also giving me the possibility to work live on the cylinder, for example porting the exhaust port to the dimensions that I was needing, create a paper template for expanding exhaust and transfers areas.

Results: This project required more than one year of meticulous work and today after 40 hours the piston has reached the end of its life, the engine performed admirably gaining a better accelleration and top speed, a rotation speed above 12000RPM which for the stock 154cc cylinder was unthinkable, power can be improved more with a 38mm carburetor and a programmable CDI.